Visual inspections systems: what they are

We design and manufacture innovative visual inspection systems capable of adapting to various production needs in terms of materials to be inspected, defects to be identified, sorting times, and logistical requirements.

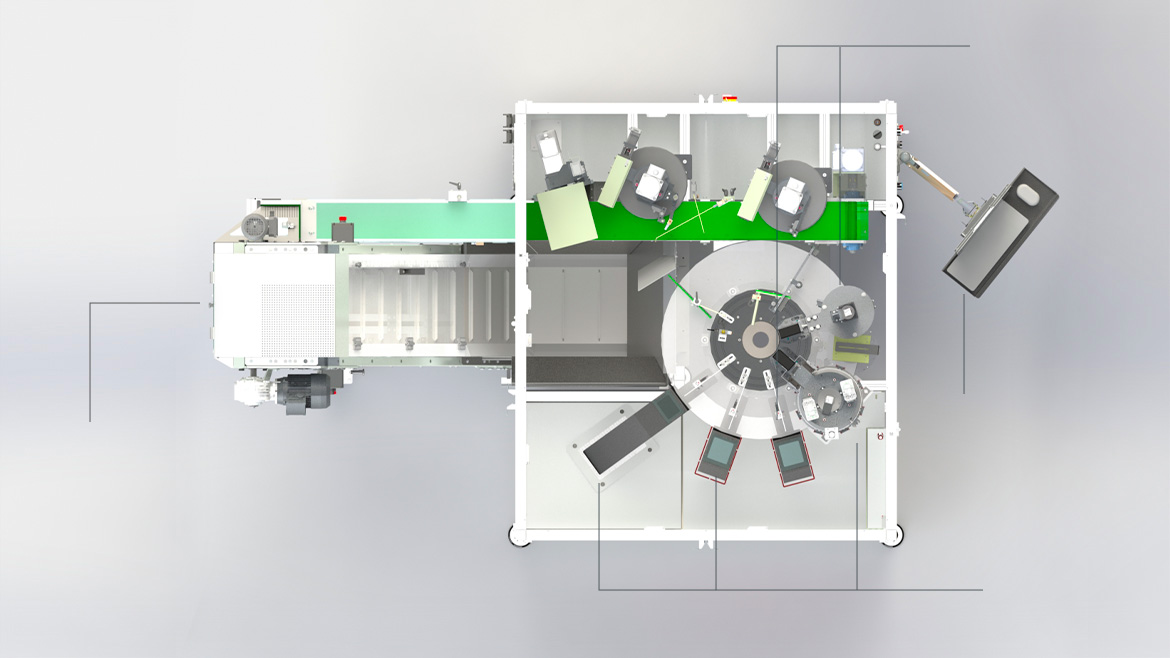

- Items are loaded into a hopper or other loading system and conveyed individually onto the inspection table.

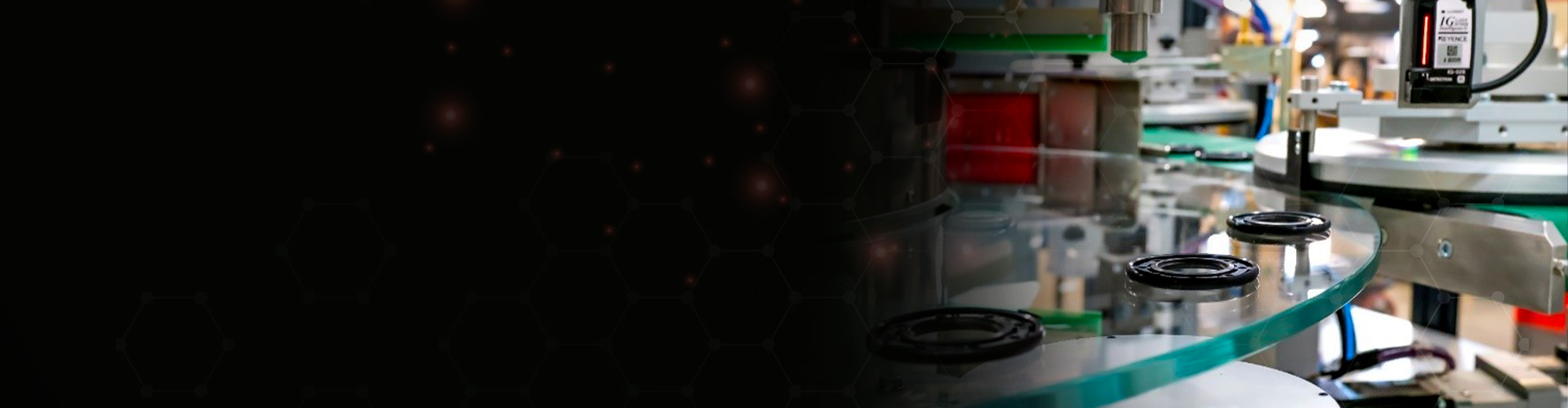

Images are captured using cameras and lighting setups.

The acquired images are analyzed using software based on processing algorithms.

Defective parts are separated from non-defective parts.

It is possible to detect different types of defects so that the parts can be separated based on the type of non-conformity identified.

-

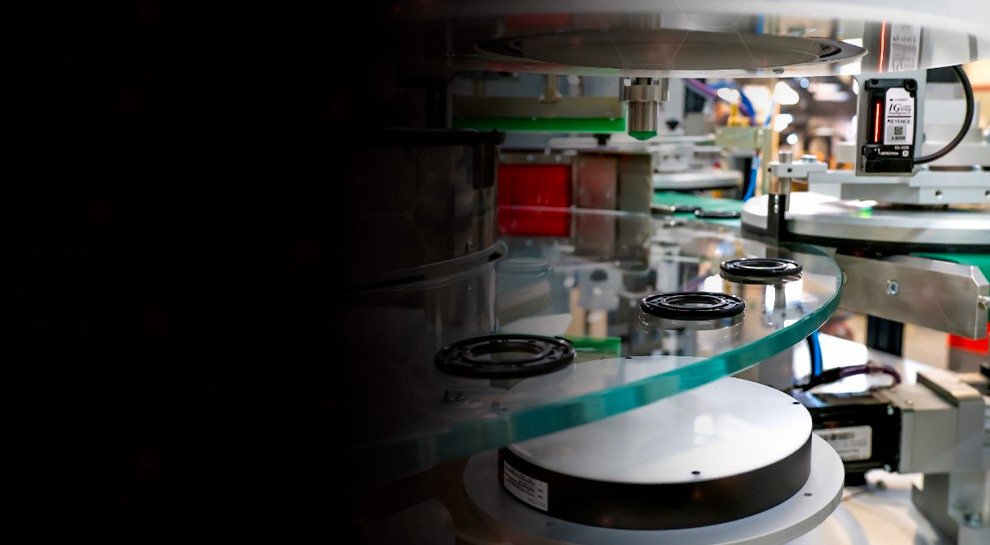

Feeding system

Parts are loaded into the machine by the loading systems.

-

Inspection units

Parts pass throught various units (superficial, peripheral or laser station) by rotating table, or belts, or pick & place system.

-

Software elaboration

Software inspects the images of the parts taken by the inspection units.

-

Separation of Parts

The compliant parts are separated from the non-compliant parts and placed in specific boxes or in a packaging system.

Visual inspection systems: why use them

Visual inspection systems offer a state-of-the-art solution that will provide extraordinary support in your company's growth.

Request information

For more information about our company or products, or if you have a question or require clarification, call us or fill out the form located next to this message. Our staff will get back to you as soon as possible.

Call us

Or write to us