Your Quality,

Our Vision.

We make the difference together.

Proven solution

Since 1995, we've been designing and developing automatic quality control systems for a wide variety of sectors: industrial, automotive, pharmaceutical, precision metal components, and fashion accessories.

Always by your side

We listen to your needs and identify the best solutions together. Our internal team of qualified engineers and technicians provides support, from feasibility studies to post-sales assistance.

Global support

With our three locations worldwide and highly qualified personnel dedicated to providing accurate and rapid responses, we work to ensure that you have zero non-conformities.

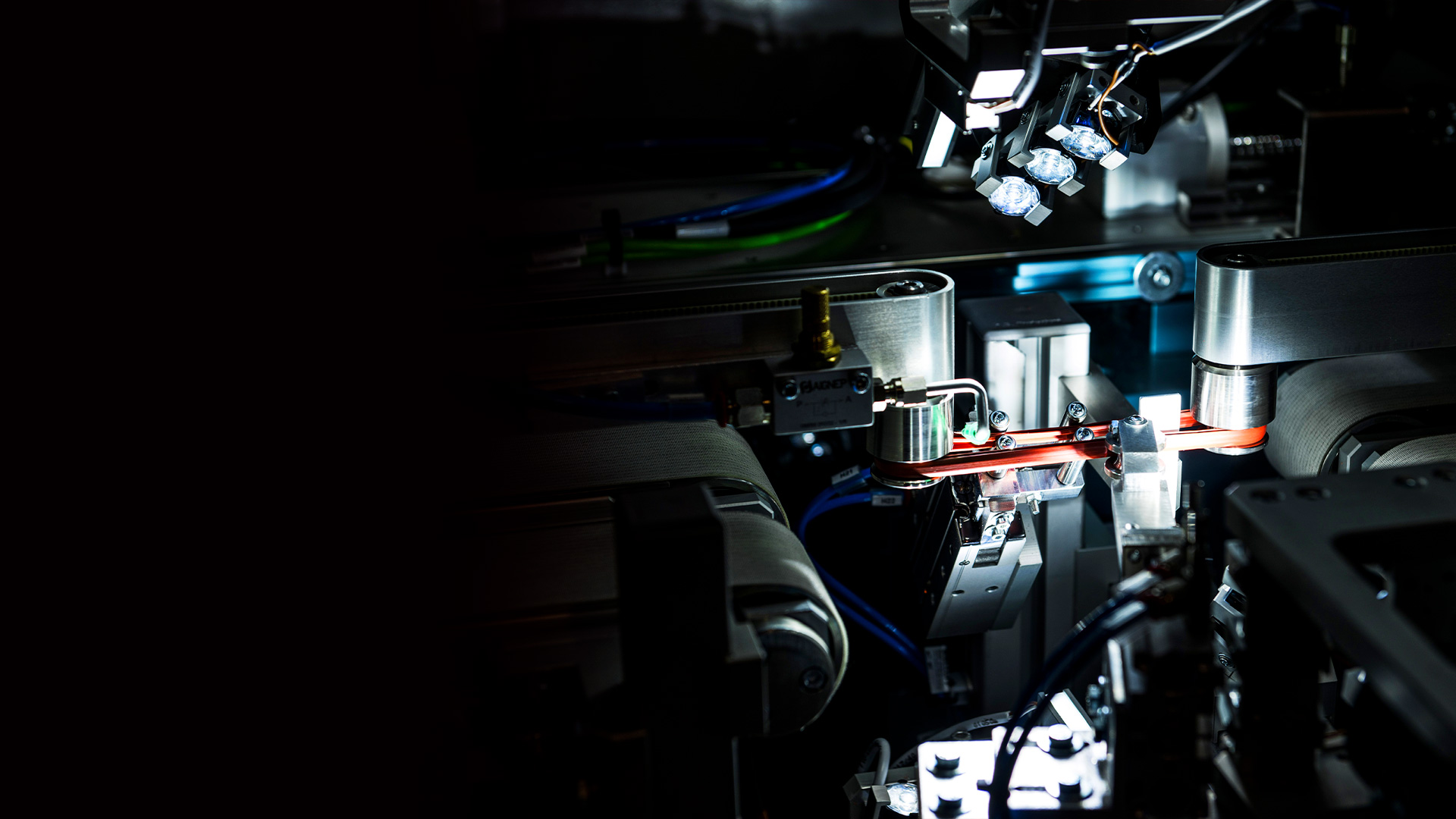

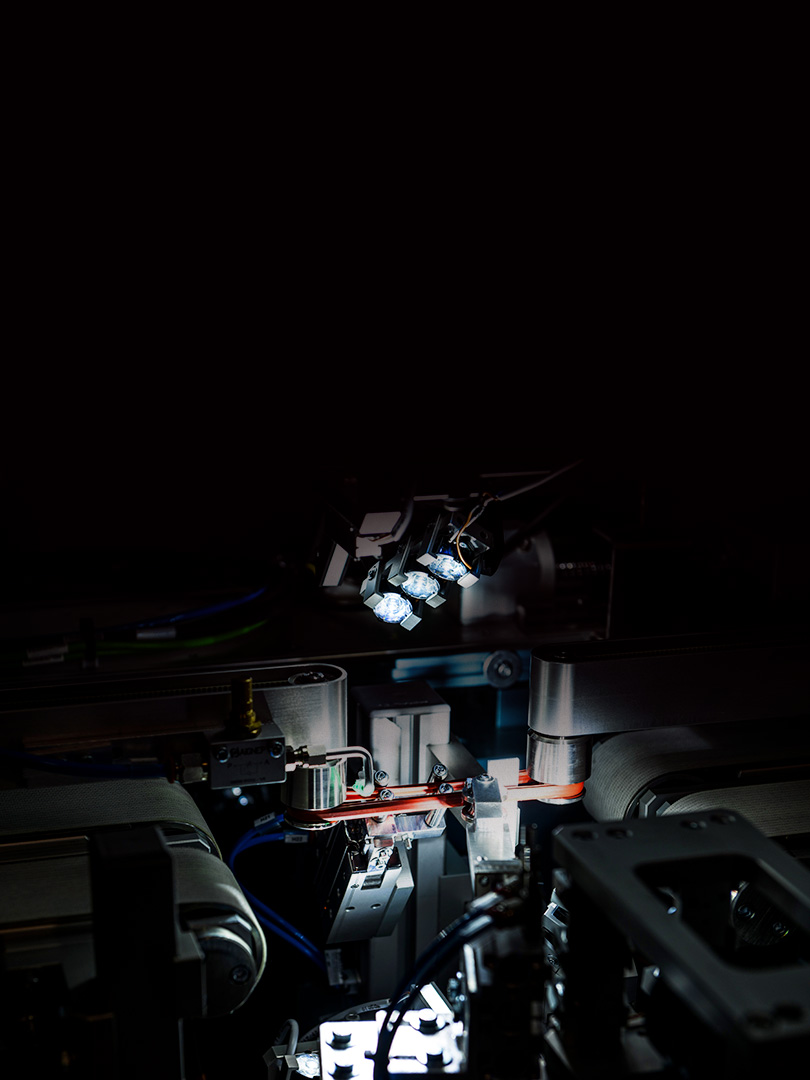

Visual Inspection Systems

Our decades of experience and well-established internal expertise allow us to guarantee proven solutions for many sectors, including, but not limited to, the industrial, automotive, pharmaceutical, precision metal components, and fashion accessories sectors.

Browse range of products

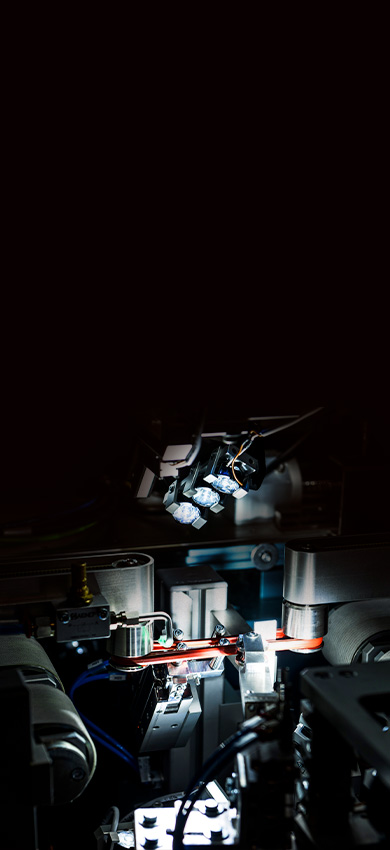

dsMIND

With dsMIND we welcome the use of artificial intelligence in the world of automated visual inspection and open the door to a series of new opportunities that will revolutionize your production process.

Discover DS MIND

Maintenance & Assistance

Customer care is our top priority. That's why we provide dedicated assistance and maintenance services to support your business’s continuous improvement.

Browse assistance services