dsMAX

Inspection without limits

dsMAX is dedicated to the visual inspection of large parts thanks to a manipulator robot that handles the movement and positioning of the parts.

- Inspection of unique parts

- Integrated DS MIND

- Optimized production process

- Integration with HPC supercomputers

Inspections

- Profile for detecting flashes and incomplete fills

- Dimensional

- External and internal surfaces

- Presence of cuts, fractures, or bubbles

Standard equipment

- Color cameras

- Dimensional measurement station

- 5 surface inspection station

- DOSS standard elevator loading system

Optional

- Multishot

- Screw loading system

- Packaging machine

Description

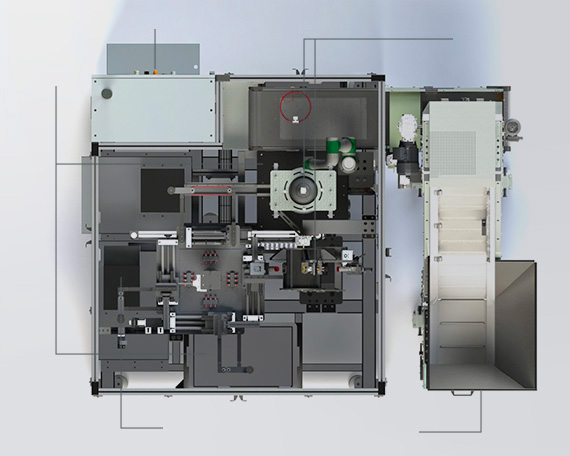

dsMAX enables the visual inspection of parts that are too large for glass tables to manage, thanks to a manipulator robot that handles the movement of the parts. DS MAX is the first inspection machine that seamlessly integrates the new dsMIND operating system, allowing you to leap into the future and providing an opportunity to revolutionize your production system.

Through the loading system, the parts are placed in an orderly manner on a conveyor belt, from which the robotic gripping system picks them up one by one and transports them inside the machine. There, the dimensional measurement is carried out first, after which, using a pulley system, the pieces are tensioned and rotated in preparation for the surface inspection. Finally they are sorted into good and defective parts.

- Statistics and reports

- Batch traceability

- Remote management

- Interacts with management software (M.E.S.)

-

Feeding system

Parts are loaded into the machine by the loading systems.

-

Inspection units

Parts pass throught various units (superficial, peripheral or laser station) by rotating table, or belts, or pick & place system.

-

Software elaboration

Software inspects the images of the parts taken by the inspection units.

-

Parts Rejection

If defect are detected parts will be rejected.

-

‘Good’ part collection

If partes pass all controlled parameters, they will be collected in ‘good’ bin or packing system.

Technical characteristics

ITEMS/PARTS

| Type of Parts | Inspection of larger parts as compared to those in the range of tabletop machines |

| Color | All, not transparent |

| Minimum diameter | 80 mm |

| Maximum diameter | 200 mm |

| Minimum height | Chord 1 mm |

| Maximum height | Chord 6 mm |

VISION

| Camera Resolution | 2.3 (superficial) and 12.3 (dimensional) |

| Type of field | Fixed |

| Framed field | 45 mm |

| Color or B/W | Color |

CHARACTERISTICS

| Maximum number of view stations | 2 |

| N. part exits | 2 good / 2 defective |

| Inspection time | 3 seconds per part |

| Type of part exit | Shoot and/or belt |

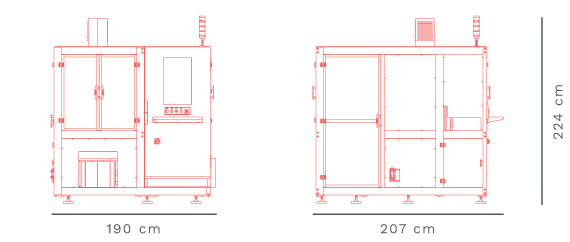

Size

Request information

For more information about our company or products, or if you have a question or require clarification, call us or fill out the form located next to this message. Our staff will get back to you as soon as possible.

Call us

Or write to us